Dynamic Induction

Dynamic Induction only detects a very limited range of the total induced AC signal that the dust induces onto the sensor's rod as it passes near it. Dynamic Induction has a lot of benefits over traditional triboelectric techniques.

- No signal transfer loss

- Larger monitoring zone

- Less maintenance issues

- Advanced QA checks

- Reliable & responsive dust readings

Besides having an advanced sensing technology, we also have a patented Rod Isolation Check (RIC) which measures the build up of dust, moisture or condensation which could it affect your dust readings. The RIC can tell you when it needs to cleaned, which saves unnecessary maintenance efforts.

No Signal Transfer Loss

Like other charge-based sensing technologies, our sensors have an enclosure with rod coming out of it.

The sensor’s rod is the “antenna” that is inserted into the gas stream being monitored.

As particles pass near and impact the rod, charges are transferred and induce on to the rod.

The direct impact signals, Triboelectric Effect or DC signals, are completed filtered out and Dynamic Induction™ only measures a limited frequency range of the induced alternating current (AC).

Eliminating the DC portion of the signal and focusing on a very key frequency range results in a very stable and responsive dust reading.

Dynamic Induction has one of the largest operating ranges of any sensor on the market.

But where other manufacturers “dumb” down their lesser sensors and limit the operating range, all of our sensors; Scout, Atlas and Titan models, are based on the same analysis platform so that they all provide the same high level of dust detection.

The DC portion of the signal, Triboelectric Effect, requires that particles directly impact the sensing rod to transfer the DC charge.

Any build-up on the rod or material changes can affect the transfer rate of the charge to the rod.

Monitoring the AC portion of the signal means that it is not affect by solids build-up on the sensor’s rod and has shown no affects or bias to changes in gas velocity.

Larger Monitoring Zone

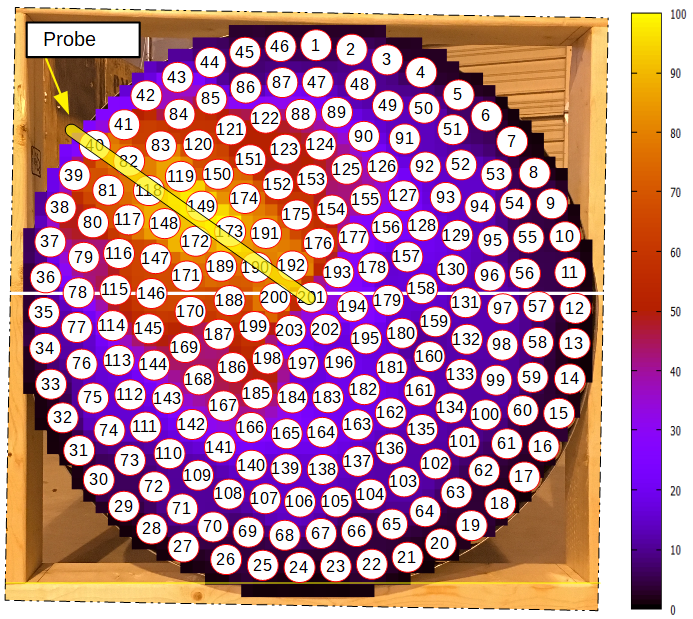

Several tests have been conducted over the years to demonstrate how Dynamic Induction technology has a much larger monitoring zone and therefore provides a more representative dust reading than other technologies.

During recent testing in our offices we created air stream with highly stratified particulate.

A copy of the testing summary is here.

Technology Benefits

Overall Dynamic Induction provides a reliable and responsive dust signal which allows you to better control your filter.

It also less maintenance than traditional tribo units which allows you to focus on the filter.

Due to the AC induction technique, the sensor’s dust reading is not affected by build-up on the rod.

This means it can go longer without being cleaned which results in less required maintenance.

And using the patented Rod Isolation Check eliminates unnecessary inspections by letting you know when it needs to be cleaned.

Work by others have shown that the AC portion of the signal is less affected by velocity changes, especially in the expection operating ranges of most filters.

Coated probes can be used, but are not recommended.

Coated proibes provide a false sense of security about less maintenance.

If solids build-up over the coating and short-circuit to the process wall a Faraday cage can be built around the sensor rod blocking out incomming dust signals.

It should also be noted that if applied incorrectly, especially in low dust applications, a coated probe can generate false dust signals from the build-up of static charge on the coating material.